Screenprinting is the process which consists of making use of incredibly thin and even levels of colour on to a surface area (which could be paper, material, wooden, steel – rather a lot anything flat). The colour is pushed by a high-quality mesh monitor, which is stretched in excess of a square or rectangular frame. An impression is built by masking parts of the display screen to end the colour from going through those people parts of the screen. These kinds of a mask can be manufactured in a wide range of approaches. A mask can be uncovered to a display screen which has been coated in a mild sensitive emulsion, or a painterly mask can be applied freehand by the artist using drawing fluid. However as a newcomer to this procedure I have liked functioning with uncomplicated paper stencils for generating a mask. This short article delivers some guidelines on how to get started off with screenprint, making use of simple machines which is easy to use at home or in a smaller operating area.

Contents of the Daler Rowney Screenprinting Beginners’ set

Suggested Materials for Screenprinting

Daler Rowney Display Printing Set

Added Screen Printing Medium (optional)

Speedball Hinge Clamps

A board to screw your hinge clamps to (Plywood or MDF)

Newsprint

Scalpel

Reducing Mat

Paper to print on to (I used Fabriano Rosaspina but you can use any paper of about 190gsm or additional)

Pots with airtight lids

Brown Parcel Tape

Pencil (to attract on to newsprint with)

Apron

Masking Tape

Little parts of card (mountboard offcuts are perfect if you have any)

You will also need to have somewhere to place the prints to dry – a clear table major or a string hung up with pegs is excellent, if you really do not have a printmaker’s drying rack.

The Daler Rowney Screenprinting Beginner’s set is a good financial commitment if you want to attempt the approach at home or in your studio with out needing to commit in a vacuum desk or carousel. In the established you will get a fantastic excellent screen and squeegee along with a most important color set of acrylics, screenprint medium for fabric and paper, and a bottle of drawing fluid. You also get a durable plastic palette knife, which is preferable to use with the monitor to a metal palette knife which is extra very likely to tear a gap in the display screen.

Before you begin, I advise that you take the time to use a pair of coats of yacht varnish to your squeegee cope with and the body of your display. This is since they are created from uncoated wooden, and if you get to a place of screenprinting consistently, recurrent washing of your tools with water may well inevitably cause premature putting on of the wooden. The yacht varnish will aid extend the lifespan of the squeegee and the monitor.

In addition to the screenprinting established, Speedball’s screenprinting clamps, and a strong board you can use as a screenprinting desk are two other pieces of products worthy of investing in. The board can just be any piece of primed or coated MDF or plywood that you can wipe moist paint from, that is a couple of centimetres bigger than your monitor (at the very least). If you have a do the job bench in your studio that you really do not sense far too treasured about that has a clean surface, you could easily use this, so lengthy as you do not mind screwing the clamps into the leading of it! The clamps must be about 10cm in from possibly facet of the display and parallel to one an additional. If you have the usually means to chisel a square into your board so the decreased part of the grip sits level with the floor of the board, this would help to maximise the printing space of the display screen, but it’s not vital.

As soon as your clamps are in spot you can put your screen in place to make your screenprinting desk.

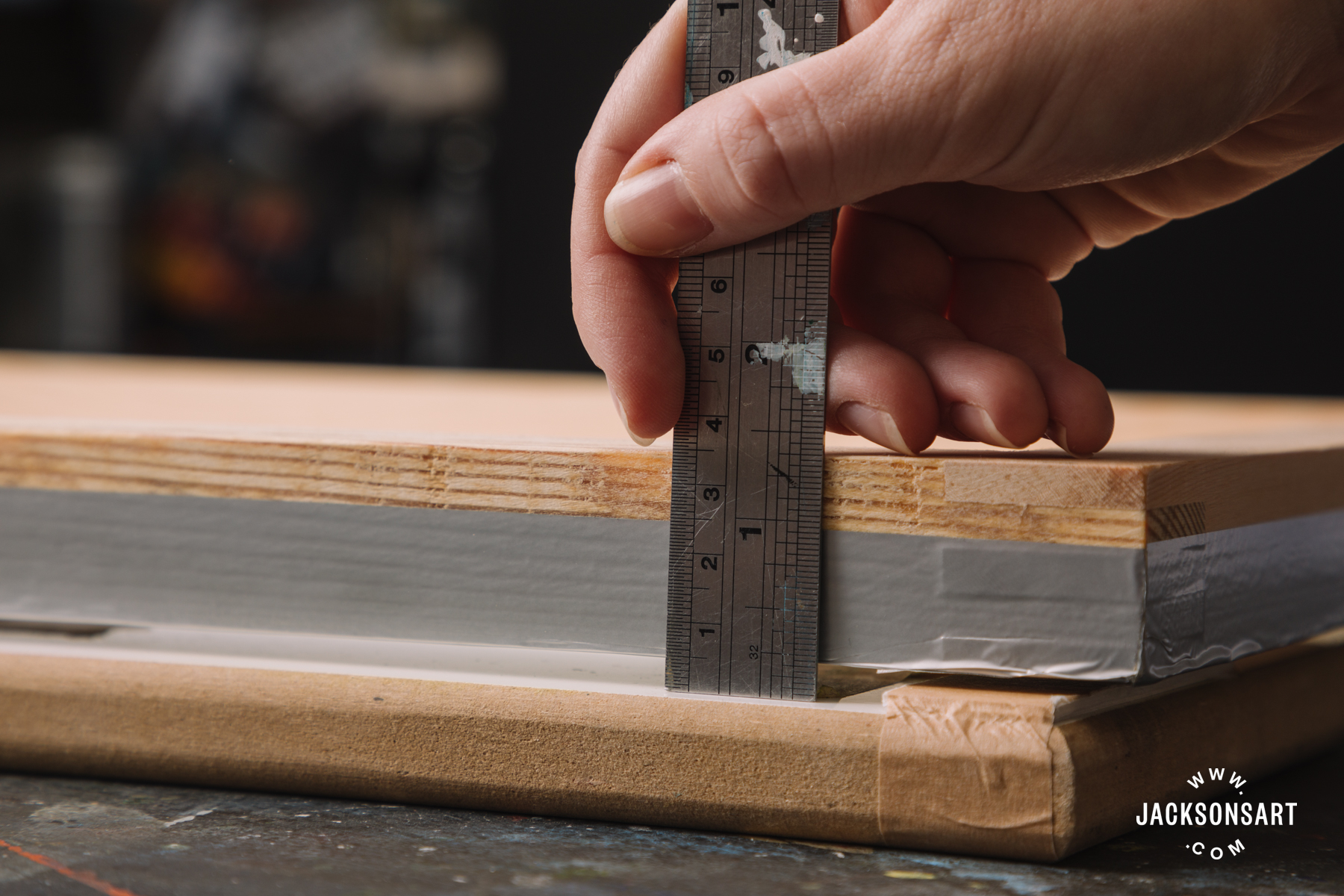

Measuring the hole in between the display and the board – this hole needs to be the similar distance at both equally ends of the monitor to accomplish a awesome even print. You may possibly want to tape an offcut of mountboard at the opposite conclusion of the clamps to accomplish this.

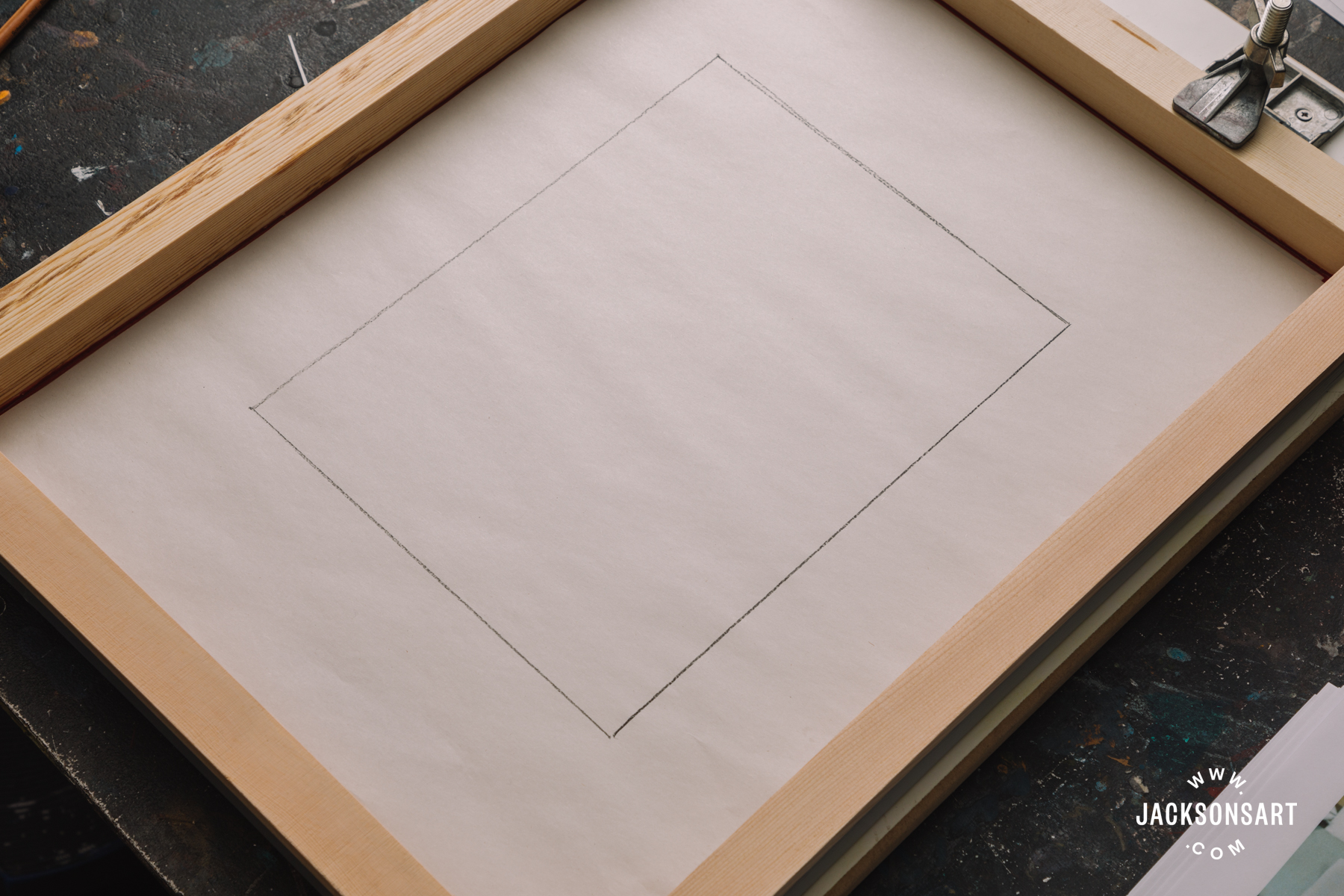

When making a screenprint, you can’t pull a print that is the exact dimensions as your display. This is since pulling a print entails a downwards and forwards force with your squeegee, which pushes the display down to the area you are printing on. As the body holds the display taut, there will generally be a border all around the inside of edge of the screen that will not make the suitable sum of contact essential with the paper for a sucessful print. When you are beginning out, I would usually suggest beginning with a tiny picture as they are a lot easier to print, and then as you boost your printing procedure, you can feel about making larger sized illustrations or photos. The rectangle I have drawn on this piece of newsprint minimize to the very same dimensions as the monitor is an indicator of the form of dimensions of impression I would recommend you start off with it is also the dimension of the impression I created for this post. Try to retain your image/printing region as central on your display as feasible.

Newsprint is the ideal stencilling product for screenprint. It is thin but robust more than enough to withstand the paint/ink, and when it is utilised as a stencil in screenprint it usually sticks with simplicity to the display screen, permitting you to use the same stencil for a variety of prints – a minimal version, if you will! It is properly standard for it to take a several attempts ahead of you get the procedure of pulling a print right, so it is often value printing a quantity of photographs in case subsequent levels of color really don’t rather go to prepare.

You can then start to slash your initial stencil from the sheet of newsprint. I preferred to print a easy nevertheless everyday living of oranges on a gingham table fabric in a amount of layers, so I began by reducing horizontal stripes across the desk area of the picture working with a craft knife.

After I experienced accomplished this I cut my printing paper to measurement. Fabriano Rosaspina is my paper of preference as it has a very good body weight to it which means it doesn’t wrinkle when printed on to. You could use any other rather weighty printmaking paper or cartridge paper (190gsm+, and clean). I slash the Rosaspina to the similar dimensions as the monitor/piece of newsprint I employed for my very first stencil.

You are going to then want to tape some registration guides to your board. There would preferably be a single to guideline the duration of your paper together one side, and then yet another to guidebook the bottom edge of your paper. A mountboard offcut or a piece of cardboard is best for this, taped down with masking tape. By making sure your paper is placed in opposition to these two guides your printed picture will be positioned in the very same position on just about every sheet, which will in flip be certain suitable registration for subsequent layers of colour.

Area your to start with sheet of paper to print on inside your guides, and then place your very first stencil on leading of this. Your might pick to print on a sheet of newsprint or a scrap piece of paper very first, so you can see if the stencil works and the printed layer seems how you would like it to.

You can then provide your screen down on to your stencil and paper.

Next, it is value taping the edges of your display screen with parcel tape, or unique ‘blue’ tape for this objective. This is accomplished to the back again of the monitor and proficiently delivers a border that stops the newsprint stencil from performing all the challenging function. The tape is a waterproof mask for the edges of your print. It is value taping ideal up to the edges of the printing region, and then remembering to remove this tape when your image is completed. If you depart the tape on the display screen for weeks on end the glue may well commence to clog the mesh.

Make positive you are employing the ideal medium (i.e. for paper alternatively than cloth), and blend extensively so the ‘ink’ is reliable all through. It’s superior to continue to keep your ink in an airtight pot in case you need to have it at a later on date. If you require it to continue to be moist for a handful of days or even weeks, you may want to also add some retarder to the system to slow the drying even further, although the screen printing medium will also sluggish drying to a diploma.

Subsequent, you need to have to put a generous volume of color on the edge closest to you, an even strip of color along the edge of the width of the picture area. Area the colour on the tape to make sure it doesn’t leak by to your paper just however.

Then, you require to set some thing in involving the monitor and the board to make sure the display screen is lifted although you flood the monitor. A roll of masking tape is great!

Flooding the display is the method of holding the squeegee to the display screen and moving it in a wiping motion from bottom to top rated of the display screen, depositing ink evenly throughout the mesh. It takes observe to acquire a approach to do this properly across the screen, but I have uncovered pace will help, with only a small downward strain on the display. It also aids to keep the squeegee at a a lot more upright angle to the display screen not rather 90 levels, but practically, keeping the squeegee at an angle somewhat away from you. For a small picture these as this it isn’t unquestionably vital the display is thoroughly flooded, but it does assistance with an even deposit of color when you really go to pull your print. Once you have flooded your screen you can then pull a print. It is normally best apply to flood the display screen straight immediately after pulling a print as this aids to cease ink drying in the mesh.

As soon as the monitor has been flooded with colour, you can then pull your very first print. Bear in mind to get rid of the masking tape or other object keeping the display screen up! You want to keep the squeegee with both equally hands, pushing downwards with the same amount of money of tension, and with some pace, pull the squeegee toward you at a 45 diploma angle. This will press the ink that is flooding the mesh down on to your paper.

When you have pulled your print you can lift the display screen and see how the layer of color has printed. If there’s any undesirable gaps you could attempt squeegeeing the monitor once again. When you’re pleased you can get rid of the print from the board and put it somewhere to dry. Then location your masking fluid/object amongst the board and the edge of your display body and flood the display completely ready to pull your subsequent print.

Hopefully pulling the print will have pushed more than enough ink as a result of the display to act as an adhesive for the stencil, which ought to then adhere to the underside of your display and maintain it in area for the rest of your prints.

You might want to use a chinagraph or All Surface area pencil to mark on the screen body in which the hinges are attached, as this could aid uncover the ideal placement for the subsequent levels for the print to attain excellent registration.

Once you have printed all your to start with layers, scoop up as considerably of the remaining ink and place it again in your pot. It’s finest to wash your display as quickly as attainable to keep away from the ink clogging up the mesh. If you do it before long more than enough, you need to be in a position to clean up the display screen simply with water and a thoroughly clean sponge, but if that doesn’t do the position, you can use a scrubbing brush and a small washing up liquid. Check out and preserve the parcel tape where it is.

Allow all your gear to dry totally (and your prints!) in advance of performing on the up coming layer.

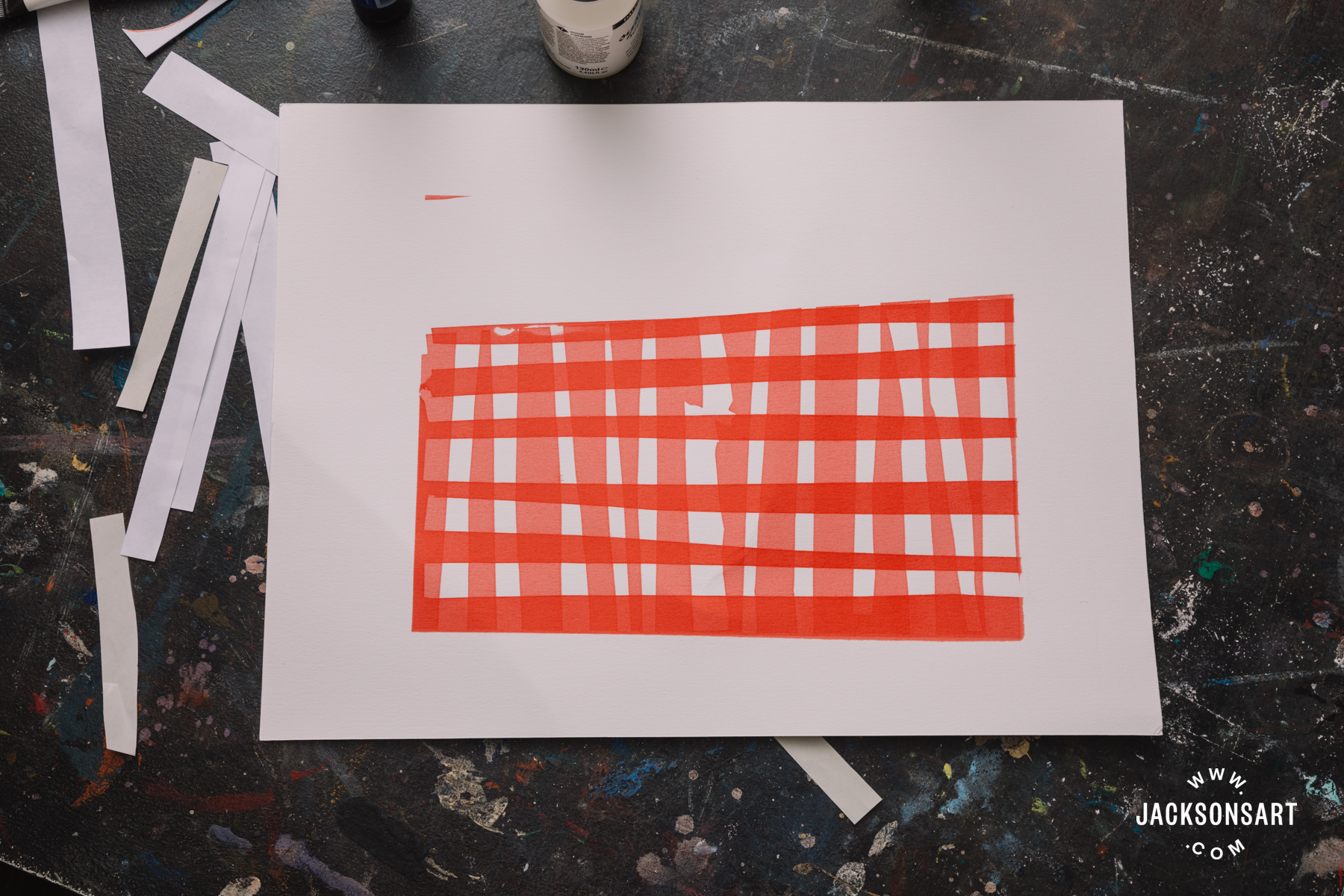

When all the prints are dry you can lower your next stencil. As my aim was to print a gingham tablecloth, my future stencil consisted of strips of newsprint placed vertically throughout my horizontal stripes.

You then will need to place your print with the new stencil positioned on prime inside the registration suggestions and placement the display screen back in the hinge clamps so the print is visible as a result of the parcel tape border.

Then it’s simply just a case of repeating the printing process, flooding then pulling the print, making certain there’s anything holding the display screen absent from the board and paper when you flood the display screen just about every time.

The a lot more medium there is added to the ink, the a lot more transparent the colour will show up, so you can see the place the layers overlap in the print at this phase – the overlapped locations surface darker. There is no limit to the amount of medium you can include to the ink, but it is finest to constantly have far more medium than paint in the ink.

Further Layers

For the up coming levels I wanted to print my fruit on the desk, and the shadows they cast. You may come across at numerous phases that tracing paper is beneficial for putting on the impression so far and mapping out exactly where the next levels need to go. You can then place your drawing experience down on to a new sheet of newsprint and attract on the back again of the traces to transfer the drawing, completely ready to cut with a scalpel. Or you could use carbon paper.

The method is repetitious for each and every layer of color, of chopping out stencils from newsprint, positioning them where you want the picture to be masked, mixing your colour, incorporating screenprinting medium, placing it on the base edge of the display prior to flooding the monitor and pulling a print. Recall to often clean the monitor as quickly just after as doable, scooping up as significantly extra ink as you can with a palette knife. The color can past for months in an airtight container, and if you do will need the ink to continue to be soaked for a when you can constantly add some acrylic retarder to it. When you have lastly completed your print take out the parcel tape quickly soon after and give the total display a superior scrub with water and washing up liquid to make sure it’s absolutely no cost of ink and all set for your subsequent screenprint version.

When you 1st start out out with monitor print, keep the image compact and basic, with just a few levels. I endorse working with stencils to begin with as the clear up procedure is comparatively effortless, and it’s feasible to make a little something easy and daring somewhat quickly. After you build self confidence by building a few prints like this, you might really feel inclined to function on a larger sized scale and perhaps even make investments in a greater display screen.

Even more Reading

Screenprinting With Dave Buonaguidi AKA Real Hackney Dave

Screenprinting With Screentec Aqua Artwork Drinking water Based mostly Monitor Ink

A Manual to Inks

Monitor Printing With Jackson’s Studio Acrylic Paint

Shop Screenprinting at jacksonsart.com

More Stories

Making Reels Work | Matt Robinson | Episode 924

Juxtapoz Magazine – Zoe McGuire: Earthshine @ Library Street Collective, Detroit

Making Art Work | Alex Olson | Episode 925